Daily maintenance of double pitch roller chain

Do the daily maintenance of the double-pitch Roller Chain and the daily maintenance of the ANSI Sprocket.

The daily maintenance of the Double Pitch Sprocket is divided into maintenance. The double-pitch roller chain production line must be stopped immediately during normal use due to normal or accidental wear and various abnormal phenomena during the production line operation. Use and report in time to prevent major accidents. Non-professional maintenance personnel or without the permission of professional maintenance personnel shall not repair by themselves.

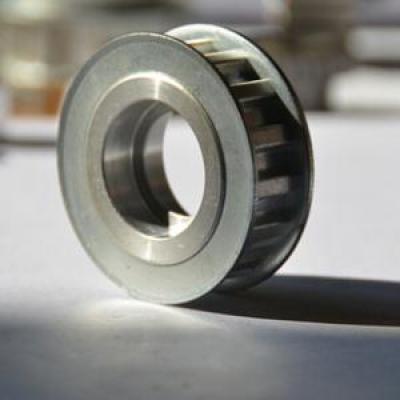

There are several types of support sprocket in a mechanical chain of a Double Pitch Roller Chain. The Gear teeth on the pair of gears contact each other to keep the gears meshing. Cogging is the gap between two adjacent teeth on a gear. The end face is a cylindrical gear or cylindrical worm, a plane perpendicular to the axis of the gear or worm. The end face is the plane at both ends of the gear. The looseness of the double-pitch roller chain mechanical sprocket should be appropriate. A curved surface is a plane that is perpendicular to the gear line.

The Double Pitch Sprocket tip circle refers to the tooth tip circle. The root circle refers to the circle where the bottom of the groove is located. The base circle forms an involute appearance line of a vortex circle. The block circle is a reference circle for calculating the geometry of the gear face. The gear industry is mainly composed of three types of enterprises: automobile gear transmission manufacturing enterprises, industrial gear transmission manufacturing enterprises and gear special equipment manufacturing enterprises.