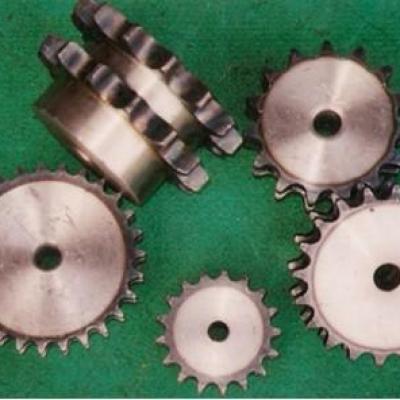

Analysis of the assembly of the power roller is inseparable from the bearing, bearing seat and sprocket

The assembly of the power roller is inseparable from the bearing, bearing seat and sprocket. The power roller conveying equipment can run very smoothly and normally. The first thing that cannot be separated is the rolling bearing. The rolling bearing of the conveying equipment is a very precise part in the parts. If it is improper, it will directly lead to the failure to obtain the expected high performance, so the precautions for the use of rolling bearings are as follows:

1. The power roller bearing must not only be used, but also the rolling bearing and the surrounding area of the bearing must be cleaned before and after each use, so that the cleaning function is to prevent dust from entering the inside of the bearing.

2. In the process of using the power roller, it is impossible to give the bearing a very violent impact, so that indentation will occur. If it is serious, the power roller will also produce cracks and breaks.

3. The operation of the power roller bearing must use professional operating tools, do not use existing tools to replace, otherwise, the power roller bearing will soon be damaged.

4. Wear gloves as much as possible during use, and be careful to operate with clean hands. The most feared thing about power roller bearings is rust. Hand sweating during operation is the main cause of rust.

5. Regularly train operators to familiarize them with the bearing usage and maintenance methods of roller conveying equipment, and to regularly supplement lubricants, and to formulate working standards for the use of power roller bearings.

6. Power roller bearings are not only precise but also relatively fragile. Maintenance is also a very important point. The normal maintenance operation method is to carry out a series of operations on the premise of not harming the bearing.

Whether the power roller conveying equipment can operate normally is inseparable from the bearing. Therefore, if the bearing is maintained, the service life of the power roller conveying equipment will also increase. The driving device transmits the power to the roller, and the support is the bearing. Only when the bearing rotates, the goods can be conveyed normally, especially for some slightly inclined upward routes.