Considerations for the design of timing pulleys

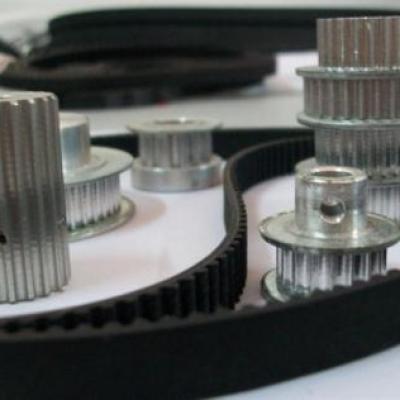

We know that the synchronous belt and the synchronous pulley are a pair of good brothers. The synchronous belt wheel is also widely used because of the widespread popularity of the synchronous belt drive. In order to ensure that the synchronous belt transmission structure can carry out normal transmission, while ensuring that the production and processing of polyurethane synchronous belts meet the standards, stable operation and reliable quality synchronous pulleys are also crucial. In order to ensure the normal operation of the synchronous pulley, we must pay attention to the following points when designing the pulley:

Parameters of synchronous pulley design

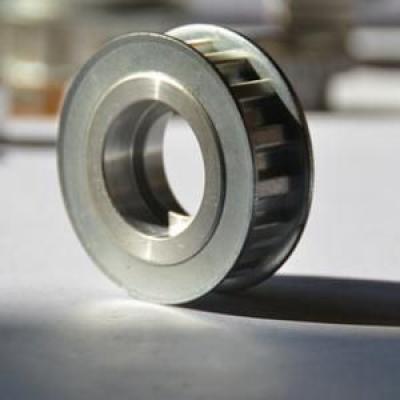

Technicians must grasp the design parameters. When designing the synchronous pulley, they need to calculate the geometric dimensions. This calculation method can make the parameters of the synchronous pulley more accurate, and the work after meeting the standards is more stable.

Simplified design

Before producing the synchronous pulley, professionals will draw the production design draft of the product. In the manuscript, the center distance of the synchronous pulley and some other important parameters need to be determined. If we already know these parameters before, we can skip this step directly to simplify the design process.

Check the strength of the synchronous pulley

Make sure that each of the above parameters is accurate, and the quality of the synchronous pulleys produced in this way is good. After we have determined some important parameters, we also need to check the strength of the Gear contact and the bending strength of the tooth root as reference data for the use of machinery. The equipment can use these data to select a suitable timing belt wheel product and timing belt to form a high-efficiency, accurate transmission transmission mechanism.