The need for hardening of industrial transmission chains

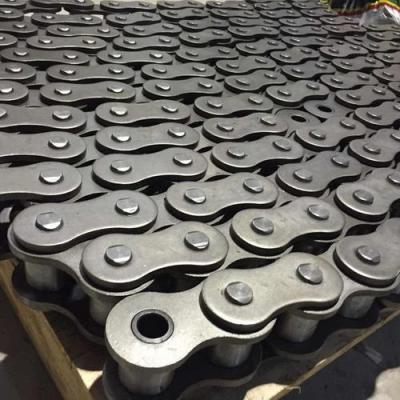

With the development of the modern industrial Transmission Chain industry, the industrial transmission chain is used in more and more occasions, but many people do not know much about the production process of the industrial transmission chain. Next, I will briefly introduce it to everyone. a bit. Generally speaking, the industrial transmission chain manufacturing process includes three steps, which are:

1. Blanking and knitting: Blanking refers to the materials required for the production of industrial chains in a pre-programmed machine. This step must be performed in strict accordance with the dimensions indicated in the chain design drawing. The knitting chain refers to the "knitting" of the processed material. This requires that the raw materials have stable hardness and good cold bendability, so as to ensure the quality of the next process.

2. Welding and "shaping": There are three commonly used welding methods: cold braided cold welding, hot braided cold welding, and hot braided hot welding. Among them, the first method is mainly used for large-scale mining industrial chains, and the second method is used to produce longer industrial chains; "shaping" consists in changing the shape of raw materials to make them closer to the shape of the chain.

3. Heat treatment: The heat treatment is completed on a special heat treatment machine. Through the action of high temperature and various auxiliary media, the structure of raw materials is improved and the performance is enhanced.

In the production process, another step is very critical, that is, quenching. The purpose of quenching is to transform the supercooled austenite into martensite or bainite to obtain martensite or bainite structure, and then mix with different Tempering at temperature to greatly improve the strength, hardness, wear resistance, fatigue strength and toughness of steel, so as to meet the different requirements of various mechanical parts and tools.

The principle of industrial drive chain quenching is to place the workpiece in an inductor wound with a hollow copper tube. After passing in intermediate frequency or high frequency alternating current, an induction current of the same frequency is formed on the surface of the workpiece, which quickly heats the surface of the part (a few seconds The temperature can be increased by 800 to 1000 degrees within a minute, and the heart is still close to room temperature. After spraying water to cool (or immerse in oil to quench), the surface layer of the workpiece is hardened.

In the process of using industrial drive chain, if you suspect that the chain is faulty, you can determine it by the following methods:

1. The sprocket, sprocket box and transmission shaft at the job site were tested and analyzed. The analysis result is that some items of the sprocket and sprocket box do not meet the design requirements, but not the main reason for the chain break.

2. In view of the possible quality problems of the transmission chain, the mechanical properties of the broken chain plate and pin are tested; the tensile load of the chain is tested. The results show that the chain meets the design requirements.

3. Designed and checked the chain transmission speed and chain selection. It was found that there were design problems with the chain drive. After analysis, this should be the main reason for the chain break.