Application of sprocket on shearer

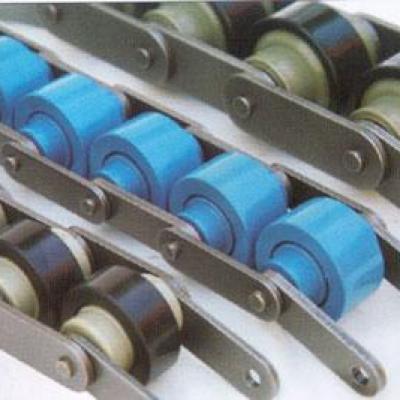

Sprockets are now widely used in various types of machinery, regardless of the size of the machinery, they may be applied to the transmission components such as sprockets, but the sprockets used in different machines are not exactly the same. The editor of the accessories will explain to you the application of the sprocket on the shearer.

Shearer is the coal mine machinery we often use. For the core parts, the seal has a great influence on the traction sprocket parts, especially in the bearing area. In general, the life of the bearing is 3- 5 years, and the replacement period of the sprocket is 3-5 months, which is a relatively bad situation. If the situation is slightly better, this refers to the ideal state. We have not made specific statistics. The period between the wear of sprocket teeth and the end of scrap.

Improper selection of sealing quality and installation position, that is, improper installation position or poor lubrication effect in the later period will cause damage to the sprocket and further affect the service life of the bearing. Different shearers have different installation methods. According to the specific situation, it can be used flexibly. Generally, there are two installation methods.

First, the traction sprocket of the SL500 shearer is added with a transition sleeve, and an O-ring is added to each end of the transition sleeve. When assembling the sprocket, it is required to inject grease from the oil injection nozzle, and stop filling until the oil drain hole starts to drain. Plug the oil filling hole and the oil drain hole with plugs to complete the installation and lubrication.

2. The traction sprocket of the 7LS coal shearer is sealed by the matching surface and the plane coating sealant. The sleeve of the sprocket is tightly fixed by the thread. Because the quality of the tightly fixed thread is poor, we can use some auxiliary seal Tools, such as adding rubber sleeves, or other seals, and then adding lubricant to the sprockets and bearings after the installation is completed, empty the car for a period of time to make it evenly lubricated.