Model function of large pitch sprocket

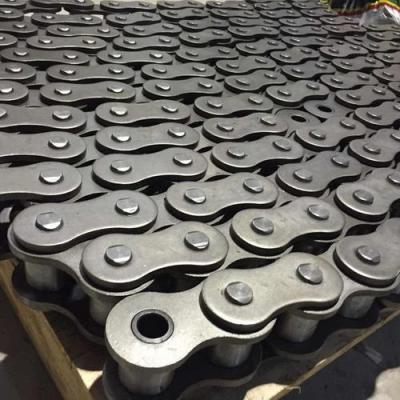

The large-pitch sprocket is a chain drive, and the Gear is driven by teeth. The international measurement unit is different. The sprocket is an inch unit. The sprocket is suitable for long-distance transmission. The sprocket does not require high design accuracy, such as the center distance It can be adapted to the center distance by changing the number of sprocket links, easy to maintain, the load capacity of the sprocket is high, the length of its gear teeth is designed to be large, and it is not easy to be disconnected from the chain. The shape is similar, but its tooth profile is not a conjugate tooth profile, and its tooth shape has great sensitivity. The sprocket tooth shape should have the following properties: to ensure the energy saving of the chain is stable and free to engage and engage; to minimize the impact and contact stress when the chain link and the sprocket are engaged; there is a larger inclusive chain pitch growth due to wear Ability; easy to process. Common tooth shapes are: straight line-arc tooth shape, two arc tooth shape. The tooth profile on both sides of the shaft surface of the Roller Chain sprocket is an arc or a straight line to facilitate the in and out of the chain link,

The structure of the large-pitch sprocket: the small-diameter sprocket is usually made into an integral type, and the medium-diameter sprocket is usually made into a spoke plate type. Made into a combined type, at this time the ring gear and the wheel core can be made of different materials!

Large pitch sprocket model: including non-standard sprocket (customized according to customer drawings), standard sprocket (American standard and metric).

The design of the large-pitch sprocket is based on the requested transmission ratio function. It has the advantages of two cams and gears. It can complete both variable-speed transmission cams and complete and efficient transmission installation. Therefore, the variable gear ratio is widely used in the circular gear machine tool industry, light industry automatic machinery, and instrument manufacturing.

Large pitch sprocket forged spiral tooth bevel gear cold completion die mold large pitch sprocket type and blank model, imitating the structure of large pitch sprocket during hot forging and cold completion forming process, received good forgings, large Pitch sprocket, tooth-shaped gear damage, equivalent strain and local principal stress and dynamic analysis of spot exchange rate and other main factors.

Commonly used sprocket processing methods

1. Forming method

This kind of tooth milling method belongs to forming method. During milling, the workpiece is installed on the indexing head of the milling machine, and a gear (or finger) cutter with a certain modulus is used to mill the gear teeth. After machining one tooth, it is indexed and the next tooth is milled. Gear milling features: simple equipment; low tool cost; low productivity; low precision of gears.

The shape of the tooth profile of the gear depends on the size of the base circle (related to the number of teeth of the gear).

The gear milling method requires simple movements, no special machine tools are needed, but the indexing head is used for indexing, and the production efficiency is low. This method is generally used to produce low-precision gears in a single small batch.

2. Exhibition method

When the gear is processed by the spreading method, the involute of the gear surface is formed by the spreading method, which has high production efficiency and processing accuracy. The vast majority of gear processing machine tools use the extension method.