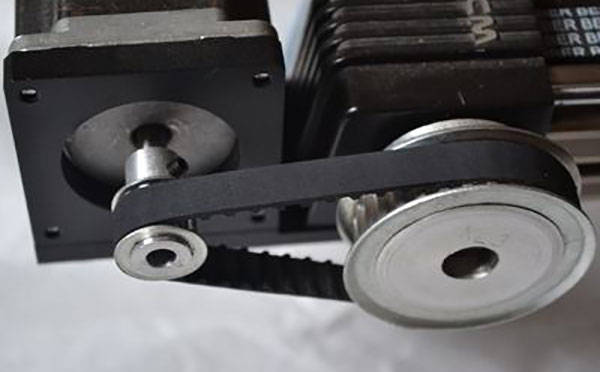

Synchronous wheel processing process introduction

If you can take different hard alloys on ordinary bedroom lathes for equipment squeezing technology for molding technology, you can tighten the ring on the synchronous wheel. When rotating the belt wheel, the ring groove will be rotated in advance on one side of the cylindrical steps in the installation ring. The light pressure assembly is used between the Gear and the strap wheels, and the squeezing is squeezed to produce deformation to tighten the ring on the belt.

If you can take different hard alloys on ordinary bedroom lathes for equipment squeezing technology for molding technology, you can tighten the ring on the synchronous wheel. When rotating the belt wheel, the ring groove will be rotated in advance on one side of the cylindrical steps in the installation ring. The light pressure assembly is used between the Gear and the strap wheels, and the squeezing is squeezed to produce deformation to tighten the ring on the belt.During the synchronous wheel processing, the required knife is a hard alloy car knife. A removing burrs refer to the removal of the micro -structural metal material particles with a very small appearance of the synchronous wheel. These research particles can be called the burrs. They are formed in cutting, grinding, milling, and other similar dandruff processing processes. Metal data is developed to high -strength, hard, and highly tough bias. The technologies of complicated overall structure components in mechanical design products have become increasingly increased, and the difficulty of removing burrs has also increased. The above -mentioned economic development requirements for removing the burrs, various social machinery, active and anti -burrs new wonderful skills and new processes came into being.

In order to improve the quality of the workpiece and extend the service life, the synchronous wheel processing process requirements, except the burrs on all metal precision parts. The workpiece must reach a very high metal surface cleanliness outside, sharp corners and edges. If necessary, it must be established for non -electroplating and electroplating and metal.