Informatization of technology, helping companies to produce synchronous pulleys

The development of computers has provided many conveniences for people. For example, people can use a computer to analyze and calculate various possible design schemes to derive actual parameters and make products. Today's technology is constantly informatizing, making many industries more accurate and easy to produce products.

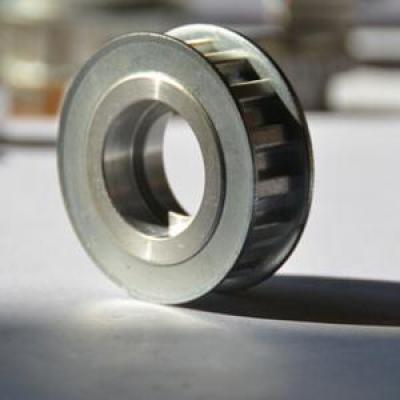

Enterprises that produce synchronous belt wheels have also developed better under the impetus of scientific and technological information. Because of the design of the timing of the Timing Pulley, it is necessary to accurately calculate the main parameters such as the area of the tooth surface contact area, the angle of the meshing line and the relative speed. If these parameters are calculated incorrectly, it will directly lead to the decrease of the accuracy of the Timing Pulley, affecting its working stability and transmission efficiency.

In the production of timing pulleys, the computer is able to calculate a number of parameters, in addition to the parameters mentioned above, as well as the calculation of elastohydrodynamic lubrication and geometric parameters. The computer has the appropriate programming to automatically calculate it accurately. Designers can also use a computer to control the cutting process of the timing pulley, making the angle of the teeth more precise and reliable.

Relevant personnel are also constantly researching new programming, allowing companies to be more precise and easy when producing

The development of computers has provided many conveniences for people. For example, people can use a computer to analyze and calculate various possible design schemes to derive actual parameters and make products. Today's technology is constantly informatizing, making many industries more accurate and easy to produce products.

Enterprises that produce synchronous belt wheels have also developed better under the impetus of scientific and technological information. Because of the design of the timing of the , it is necessary to accurately calculate the main parameters such as the area of the tooth surface contact area, the angle of the meshing line and the relative speed. If these parameters are calculated incorrectly, it will directly lead to the decrease of the accuracy of the timing pulley, affecting its working stability and transmission efficiency.

In the production of timing pulleys, the computer is able to calculate a number of parameters, in addition to the parameters mentioned above, as well as the calculation of elastohydrodynamic lubrication and geometric parameters. The computer has the appropriate programming to automatically calculate it accurately. Designers can also use a computer to control the cutting process of the HTP 14M-85 Taper Bore Timing Pulley, making the angle of the teeth more precise and reliable.

Relevant personnel are also constantly researching new programming, allowing companies to be more precise and easy when producing Timing Pulley.