Precautions and maintenance in the use of sprocket

1. When selecting the sprocket, select the model correctly according to the specifications.2. In the correct way, the active and motion -mounted wheel device are in place, and the firmware is tightened to meet the specified torque requirements.

3. After installing the Transmission Chain and adjusting the looseness, check whether the cooperation between the chain and the sprocket is smooth, and there is no intervention with the chain cover.

4. Check whether the position of the transmission of the transmission chain (the transmission output a shaft, the hub, etc.) is good. ), Otherwise, repair or replace related components.

Point manufacturers introduce the precautions in the use of sprocket wheels:

Anti -pine measures should be taken from the motorized sprocket wheel.

Regularly clean and smooth transmission chain and drive sprocket wheels to improve their service life.

Chain wheels and chains are replaced at the same time. If only one of them is replaced, the wear of both parties will be aggravated.

After loading the sprocket wheel, the application conditioner and rear shake (also known as the rear cross) are adjusted to adjust the rear wheel shaft.

Due to the high speed of the active sprocket, the number of teeth is small, the wear is faster than the motion of the sprocket under the same conditions, which is normal.

The thickness of the sprocket is standard. If there are no individual processing equipment, the electromechanical market can be available, and only the model and the number of teeth need to be proposed. If the axishole of the ready -made sprocket is not processed to the size, only a small pre -hole is required to facilitate the cooperation of the user, and then process the shaft hole and the cutter slot according to the need of the axis.

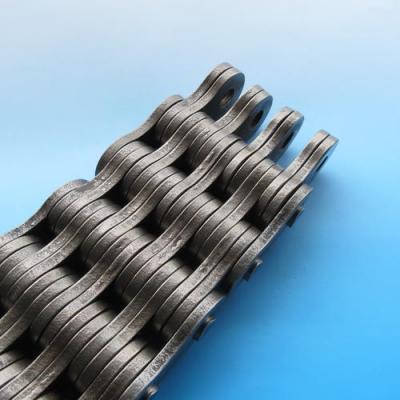

Comparison of sprocketing and transmission: Chain transmission is suitable for two wheelbases and uniform transmission ratios, but the instantaneous transmission is not strict than that of the instantaneous transmission, poor working environment (oil, dust, high temperature) and other places.

Application of sprocketing: Generally used for mechanical transmission of metallurgy, light industry, chemical, machine tools, agriculture, lifting transportation and various vehicles.

The elasticity of the sprocheter should be moderate, and the tightness will increase power consumption, and the bearings are easy to wear; overly loosening will make the sprocket easily beating and taking off the chain. The tightness of the sprocket is as follows: Lift or pressing from the middle of the sprocket, about 2%-3%of the center spacing of the two sprockets.

The non -standard link wheel should not be swinged or tilted when it is installed on the shaft. In the same transmission parts, the end surface of the two sprockets should be located in the same plane. When the center distance of the sprocket is less than 0.5 meters, it can be deviated from 1 mm; when the center distance of the sprocket is greater than 0.5 meters, it can be deviated from 2 mm. However, there must be no side of the rhine teeth. If the two -wheeled offset is too large, it is easy to take off the chain and accelerate the wear. When replacing the sprocket, pay attention to check and adjust the offset.

After the sprocket is severe, the new sprocket and new sprocket should be replaced at the same time to ensure good meshing. The new sprocket or new sprocket cannot be replaced separately. Otherwise, the meshing will not be good, accelerate the wear of the new sprocket or new sprocket. After the spindle surface is worn to the degree, it should be flipped in time (referring to the mixed surface wheels) to extend the use time.

The new sprocket is too long or after use, which is difficult to adjust. The chain section can be removed according to the situation, but it is even. The link should be passed from the opposite side of the sprocket, and the locks are inserted outside.

The spindle should be refueling in time during the work. The coordination gap between the oil into the roller and the inner sleeve to reduce wear.

Old sprockets cannot be mixed with local new sprockets, otherwise it will easily impact the transmission and break the spinth wheel.

When the machine is stored for a long time, the sprocket should be removed, clean it with kerosene or diesel, and then apply oil or butter to store it in the dull center.