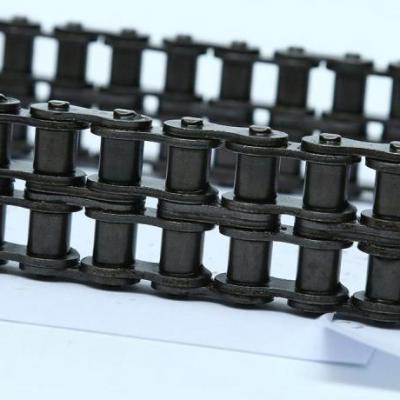

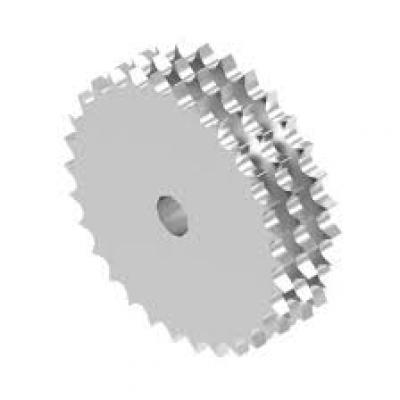

For sprocket processing with fixed structure and large output

For the sprocket processing with a fixed structure and a large production volume, it is mostly realized by the design of a special machine tool. The application of a special machine tool to process the link has higher processing efficiency and lower cost. However, the design and manufacture of special machine tools is very difficult, and the variety of processed products is relatively single. With the emergence and application of CNC boring and milling machines, the use of CNC boring and milling machines for sprocket processing has a better quality of sprocket processing and supports multiple structural forms of sprocket processing, but this type of sprocket processing has a higher cost. With the practice and discovery, a special chain socket milling cutter and a special fixture can be designed to process the sprocket on an ordinary milling machine. Ordinary milling machine processing sprocket quality is better, supporting different pitch circle sprocket processing, better processing efficiency, excellent economy, can effectively solve the problem of single piece and small batch sprocket processing. The main idea of machining a sprocket with an ordinary milling machine is based on the current status of sprocket processing. For a large number of structural sprocket processing, a professional CNC milling machine design is required. Its processing stability is good, but its application also has certain limitations. For example, the design of a special milling machine is very difficult, and the type of product processing is very simple. This method cannot achieve the production of sprocket with specific specifications, and it is not applicable to the processing of single sprocket and small batch sprocket. In order to realize the processing of sprocket wheels with ordinary milling machines, special fixtures should be designed, and special chain socket milling cutters should be used to process sprocket wheels with ordinary milling machines. The cost is lower, the processing quality and efficiency are better. Comprehensive advantages are obvious.