Maintenance Skills of Steel Welded Bending Chain for Engineering

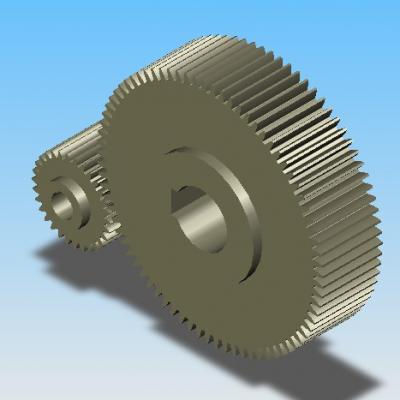

1. The sprockets of the steel welding bent plate chain for engineering should be installed on the shaft without skew and swing. In the same transmission assembly, the end faces of the two sprockets should be in the same plane. When the center distance of the sprocket is below 0.5 meters, the allowable deviation is 1 mm; when the center distance of the sprocket is above 0.5 meters, the allowable deviation is 2 mm.

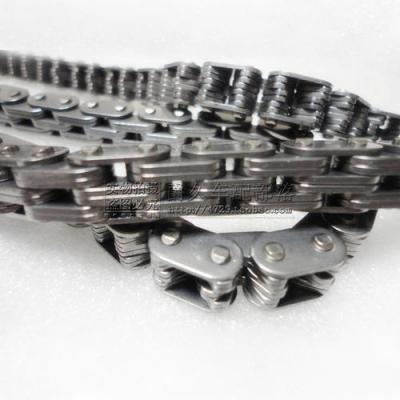

2. The tightness of the steel welded bent plate chain for engineering should be appropriate. Too tight will increase power consumption and the bearing is easy to wear; too loose chain is easy to jump and delink. The tightness of the chain is: lifted or pressed from the middle of the chain, the center distance between the two sprockets is about 2-3%.

3. The new chain is too long or elongated after use, it is difficult to adjust, the chain link can be removed depending on the situation, but it must be an even number. The chain link should pass through the back of the chain, the locking piece should be inserted outside, and the opening of the locking piece should be in the opposite direction of rotation.

4. After the sprocket wears seriously, the new sprocket and new chain should be replaced at the same time to ensure good meshing. It is not possible to replace new chains or sprockets alone. Otherwise, it will cause poor meshing and accelerate the wear of the new chain or new sprocket.

5. The old chain can not be mixed with some new chains, otherwise it is easy to produce impact in the transmission and break the chain.

6. The steel welded bent plate chain for engineering should be filled with lubricant in time. Lubricating oil must enter the matching gap between the roller and the inner sleeve to improve working conditions and reduce wear.