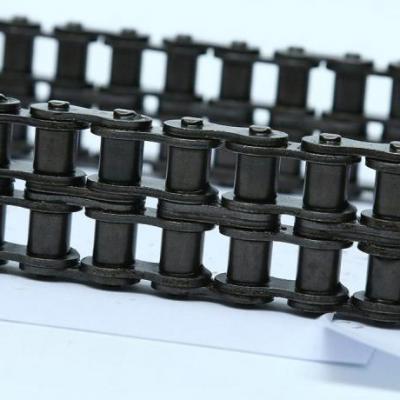

Teach you how to distinguish the quality of industrial drive chains

The industrial Transmission Chain is made of high-quality alloy steel using advanced chain-making equipment and advanced chain-making technology. The main materials are 20Mn2, 25MnV, 23MnNiMoCr54, and its range is: Φ6-Φ32. Different sections can also be made according to customer needs. Isometric chain. Industrial transmission chain has the advantages of high strength, wear resistance, light weight, etc. It is suitable for more complicated working conditions, and the safety factor is 4 times.

1. The main rope of the industrial transmission chain must be correctly selected, and it is strictly prohibited to mix it.

2, The self-locking device must be installed correctly, and the roller (the protruding part) is on the upper part.

3. Before installing the industrial transmission chain, please withdraw the safety screw and press the pawl and roller assembly in the counterclockwise direction according to the opening direction of the claw shaft. After installing the main rope of the industrial transmission chain, load it clockwise according to the opening direction. Then close the fuse and screw the fuse (not too tight).

4. After the main rope is installed, the up and down flexibility of the self-locking device should be checked. If the self-locking device is not flexible, the half tension spring can be adjusted appropriately. And try to lock 1 to 3 times to ensure that the lock function is normal. If you find that the industrial transmission chain is abnormal, you must stop using it; and contact the factory. Unauthorized loading and unloading is strictly prohibited.

5. After one year of use, one or two self-locking devices with large abrasion should be taken out from the industrial transmission chain, and 80kg weights should be used for free-fall impact test. If there is no abnormality, this batch can continue to be used for 3 months. After that, every 3 months should be tested according to the use situation. Products that have been tested or impacted by heavy objects must not be used.

Industrial drive chain

Industrial drive chain is a part of hoisting hoist, which can lift heavy objects. Some chains break during use, which affects the safety of operation. So what's going on with the chain breaking? Let me give you a detailed introduction.

For industrial transmission chain fracture, it is mainly caused by improper user operation and chain quality failure.

Improper operation of industrial transmission chains by users mainly includes overloading operations, oblique lifting, etc., which will increase the chain's bearing capacity and overload the rated load, which will easily deform and break the chain.

Insufficient quality of industrial transmission chain will increase the fracture situation, because the chain does not meet the national standards during production, there are loopholes in quality. When the user lifts the chain, the chain will be stressed and prolonged use will cause the chain to break.

许多 Many factors that affect the quality of industrial transmission chains. No matter what kind of product is produced, there will be more or less influential factors in the production process. The industrial transmission chain is no exception, let's take a look at those factors that affect the quality of industrial transmission chains.

1. Industrial transmission chain scale size and weight: The iron chain should be fully immersed in zinc solution at one time so as to reach a uniform galvanized film arrangement. If it is too long or too wide, it is necessary to dip the workers twice. The appearance of the zinc layer will appear rough and too thick. Otherwise, if the single weight of the iron chain is too heavy, those who exceed the load of galvanizing equipment will make their work difficult.

2. Raw material of industrial transmission chain: The raw material of iron chain will affect the arrangement and thickness of hot-dip galvanized coating, but if it is communicated in advance, it will be technically minimized.

3. Combination of dissimilar metals: For example, the industrial transmission chain is a combination of iron and non-ferrous metals such as copper, tin, lead, etc. During the hot dipping operation, the dissolution of this non-metal will change the zinc film arrangement. Another example is the combination of old and new iron chains. When pickling, the new raw materials are easily pickled.

4.Iron chain pollution: such as paint pollution, special grease pollution, etc., it is not easy to remove in ordinary alkaline degreasing liquid. At this moment, it is necessary to use special solvents to eliminate or use incineration and sandblasting methods to add cost And work is difficult. In addition, the removal of welding slag, such as welding touch, is also appropriately important.

5. Welding method: The welding method of industrial transmission chain has a great influence on the quality of hot-dip galvanized steel layout, and in severe cases, it may even crack or deform the product.

6. Questions about drawing: The layout drawing of industrial transmission chain is the primary factor for the quality of hot-dip galvanizing work. The first criterion it describes is to make the dissolved zinc active inside and outside the layout.