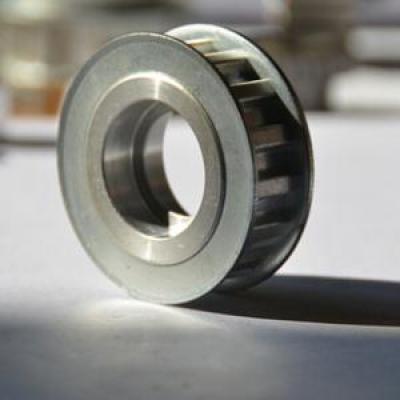

Deep groove ball bearing structural parameters

Deep groove ball bearings The original list of radial ball bearings is the most widely used type of rolling bearing. It is characterized by low friction resistance and high speed. It can be used on parts that can bear radial load or combined load acting both radial and axial. It can also be used on parts that bear axial load, such as small power motors, Automotive and tractor Gearboxes, machine tool gearboxes, general machines, tools, etc.

Bearing construction

Deep groove ball bearings have a simple structure and are easy to achieve higher manufacturing accuracy than other types, so they are convenient for mass production in series, the manufacturing cost is low, and they are extremely common. In addition to the basic type, deep groove ball bearings also have various modified structures, such as: deep groove ball bearings with dust cover, deep groove ball bearings with rubber seals, deep groove ball bearings with retaining grooves, and Deep groove ball bearing with large load capacity of ball notch, double row deep groove ball bearing.

Bearing type

Deep groove ball bearings are mainly used to support radial loads, but they are also commonly used to support combined radial and axial loads. In particular, when the speed of mechanical equipment is very high, it is not suitable to use thrust bearings. This bearing can be used to bear bidirectional pure axial load, and it requires no maintenance during work. Deep groove ball bearing models are: deep groove ball bearing (60000 type); deep groove ball bearing with outer groove (60000N type); deep groove ball with dust cover on one side and stop groove on the other side Bearing (60000-ZN type); deep groove ball bearing (60000-2ZN type) with dust cover on both sides and retaining groove on the outer ring; deep groove ball bearing (60000Z type) with dust cover on one side; both sides Deep groove ball bearing with dust cover (60000-2Z type); deep groove ball bearing with sealing ring on one side (60000-LS type, 60000-RZ type); deep groove ball bearing with sealing ring on both sides (60000- 2LS type, 60000-2RZ type); deep groove ball bearing with flanged outer ring (type F60000); deep groove ball bearing with flanged outer ring on one side (type F60000-Z); There are 11 types of flange outer ring deep groove ball bearings (F60000-2Z type). [2]

According to the size of deep groove ball bearings, it can be divided into:

(1) Miniature bearings-bearings with a nominal outer diameter range of less than 26mm;

(2) Small bearings-bearings with a nominal outer diameter range of 28-55mm;

3 (3) Small and medium-sized bearings-bearings with a nominal outer diameter range of 60-115mm;

(4) Medium and large bearings ---- bearings with a nominal outer diameter range of 120-190mm

5 (5) Large-sized bearings ---- bearings with a nominal outer diameter range of 200-430mm;

(6) Extra large bearings ---- bearings with a nominal outer diameter range of 440mm or more.

Processing form

The processing form of deep groove ball bearing parts is as follows:

1. Multi-process processing: Generally, bearing production requires 20 to 40 processes, and more than 70 processes.

2, molding processing: The working surfaces of the bearing parts are rotary molding surfaces, which are suitable for processing by molding methods.

3. Precision processing: Most surfaces of bearing parts are subjected to grinding. The size and geometric accuracy of grinding are in μm.