Escalator chain lubrication

Appropriate oiling and lubrication of the escalator chain will have a certain effect on improving the performance of the escalator and extending its service life. This article describes a new and efficient way to lubricate.

1 Traditional lubrication method

The lubrication of the escalator chain has manual lubrication device and automatic lubrication device. Both of the traditional oiling methods-drip method and spray method are used to improve the performance of the escalator and extend its service life, but the relative efficiency is lower and the fuel consumption Big.

Experiments have shown that the drip lubrication method always has unlubricated links, and the chain stretching and fracture occur from those unlubricated links. And this method wastes about 30 to 70% of the lubricating oil. The spray method pollutes the surrounding environment due to the splash of oil mist, and the waste of oil is more than 60%. In addition, the oil is in the form of a mist. Under high heat and high-speed chain conditions, the oil has vaporized before dripping to the lubricating place, which can hardly achieve the purpose of lubrication.

2 Linear lubrication method

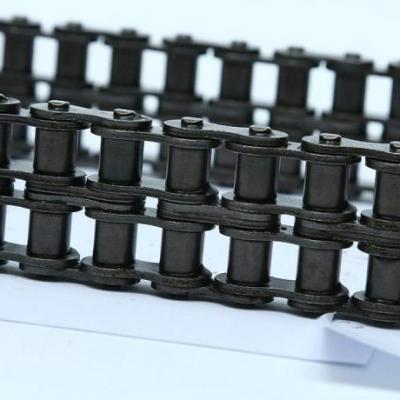

To give the chain proper and effective lubrication, let us first look at the structure of the chain. Figure 1 (click here) shows the most used sleeve Roller Chain structure. The stretching and breaking of the chain is mainly caused by the wear between the pin and the sleeve. Therefore, oil lubrication must be added between the outer chain plate and the inner chain plate. And the large amount of oil makes it fully lubricated, while also cooling the links, reducing noise and buffering. Linear lubrication can meet this requirement. However, the traditional lubrication method only provides oil to the rollers, only reduces the friction between the chain and the sprocket, and reduces the tension and prevents breakage.

The linear lubrication method refers to the lubrication method in which the lubricating oil flows from 0.3 to 0.8㎜ to the lubricating part of the lubricated parts, as shown in Figure 2 (click here), and has good directivity. Even if the chain link moves or rotates at a high speed, it can be completely and accurately injected to make it fully lubricated. The spraying amount of each nozzle is about 8-12ml per minute, which is larger than the flow rate per minute of the traditional lubrication method. Due to continuous spraying, each chain link of the moving or rotating chain can be fully lubricated once. Therefore, it can be controlled within one week of the chain operation, which is much shorter than the traditional lubrication method. The advantages of linear lubrication are: short time, low fuel consumption and good lubrication effect.

3 Conditions for achieving linear lubrication

(1) Generally based on an automatic (electric) refueling device, a pressure-resistant piping system is required; (2) An oil pump capable of outputting a large oil pressure, with a pressure of about 10 to 40 ~ f / cm2 Only under high oil pressure can the nozzle spray the linear oil path; (3) It has a linear lubrication nozzle with a structure different from that of ordinary drip and spray nozzles; (4) The position between the nozzle and the lubricated component is reasonably placed In order to spray the lubricating oil before the linear oil circuit is not dispersed.

The results show that the effect is more significant for high-speed chains or in harsh environments with dust and high temperatures.