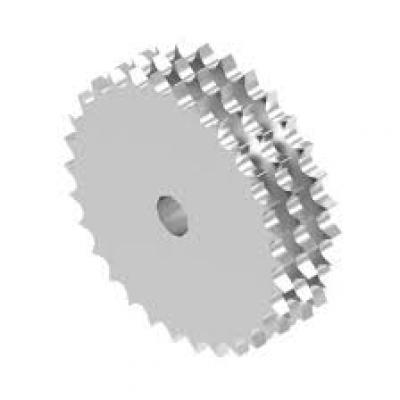

Analysis of the advantages and disadvantages of cone gears

1. The advantages of cone Gear1. Strong loading capacity: Because the angle of the gear gear surface is large, compared to other types of gears, the carrying capacity of the gear is stronger and can withstand greater loads.

2. Stability of torque transmission: The teeth of the cone gear are specially designed and processed, which can better ensure the stability of the torque transmission, reduce the production of noise and vibration, and enhance the stability and reliability of the mechanical system.

3. High transmission efficiency: The speed of the gear surface of the gears is smaller than the type of other gears, and the friction loss is less. Therefore, the transmission efficiency is high, and it is widely used in the high -power transmission field.

Second, the disadvantages of the gear gear

1. The difficulty of manufacturing: the structure of the cone gear is more complicated, the manufacturing is more difficult, it requires high -precision processing and adjustment technology, and the cost is high.

2. High requirements for central and axial distance requirements: Due to the working principle of cone gear and the special nature of the gear structure, the requirements for central and axial distances are relatively high and need to be accurately controlled. Otherwise, it will affect the working performance and life of the gear. Essence

3. Complex space: The design and structural requirements of the gear gear are usually more fine than other gears, and the space required is more complicated. Therefore, more considerations and attention is needed during design and installation.

Based on the above, the gear gear is superior in terms of carrying capacity and torque transmission, but the difficulty of manufacturing, high requirements for central and axial distance, complex space and other shortcomings need to be considered. choose

star_border