What is a synchronous pulley

1. Working principle:The synchronous pulley is a low-speed and high-torque transmission part, which combines the advantages of belt drive, chain drive and Gear drive. ,

Second, the characteristics and advantages of synchronous pulley

• 1) Accurate transmission, no slippage during operation, and constant transmission ratio

• 2) The transmission is stable, with buffering, vibration reduction capabilities, and low noise;

• 3) High transmission efficiency, up to more than 98%, with obvious energy saving effect;

• 4) Easy maintenance, no need for lubrication, low maintenance cost;

• 5) The speed ratio range is large, generally up to 10, and the line speed can reach 50m/s

• 6) No pollution, can work normally in places where pollution is not allowed and the working environment is relatively harsh

It has the advantages of high efficiency, small size, less maintenance, no pollution, and small load on the shaft.

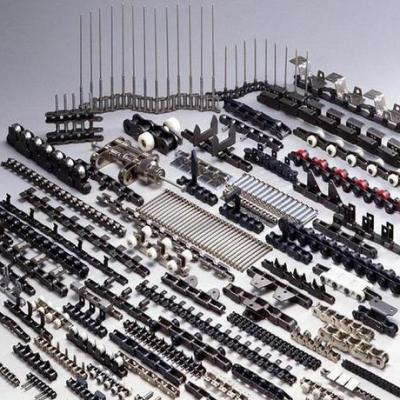

Three, model classification

Timing Pulleys are mainly classified according to tooth shape, pitch and structure.

The main tooth shapes of the synchronous pulley are:

HTD arc tooth: 3M, 5M, 8M, 14M, 20M

HTD arc teeth, the shape is a typical curved arc shape.

ISO 5294 inch teeth (straight edge/involute), MXL, XL, L, H, XH...

ISO5294 inch tooth (including straight edge/involute): the tooth side is a smooth line segment, the tooth top and

The tooth bottom has obvious excessive R, which is one of the more commonly used tooth shapes

DIN7721 T-shaped teeth, T2.5, T5, T10, T20

STD arc teeth, the shape is divided into several arcs in different directions, and

There are obvious differences in HTD arc teeth, which are more common in foreign countries.

AT tooth, AT3, AT5, AT10, AT20

The tooth profile angle of the AT-shaped tooth is larger, reaching 50°.

POLY CHAIN arc tooth, PC8M, PC14M

POLY CHAIN teeth: the sides of the two teeth are equitangent curves, and the bottom of the teeth is smooth