The knowledge of some industrial conveyor chains

I have to bring up some general knowledge about industrial Conveyor Chains, because the chain is small, but we can't do without it, we still need to understand it well:

1. Motorcycle industrial conveyor chain: It is defined by the use of the chain. It is divided into two types: the Roller Chain and the sleeve chain. It is divided from the parts used on the motorcycle. Two types are used. Most of the chains used in the engine are sleeve chain structures. The chains used outside the engine are drive chains used to drive the rear wheels. Most of them use roller chains. Such chains should pay special attention to ensuring fatigue performance.

2. Agricultural clamping industrial conveying chain: suitable for walking wheat, rice harvester, fixed-type motor rice and wheat thresher, and semi-feed combine harvester.

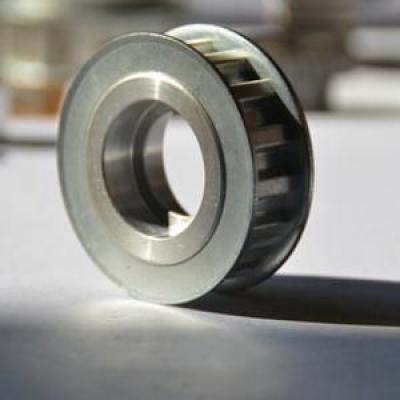

3. Industrial conveyor chain: used for transportation, single pitch, double pitch, long pitch are all available. Attachments or crossbars can be inserted into any chain link without disassembling the chain.

4. Industrial conveyor chain: used for transmission between engine crankshaft and camshaft. Because the combination of engine piston stroke and exhaust time has strict requirements, the chain for this purpose is called a timing chain. Both roller chains and toothed chains can be used as timing chains. Timing chain is mainly used for engine (diesel or gasoline) transmission of automobiles, motorcycles and ships. In order to reduce the weight of the engine, the installation clearance between the industrial conveyor chain and the engine is very small, and some do not even have a tensioning device. Therefore, in addition to the high precision requirements for the timing chain, the wear resistance is also very high.

的 The storage of industrial conveyor chains is also critical to extend life. When these parts are not in use, they cannot be placed anywhere, otherwise the quality of the chain is easily damaged. Do not store these products in a humid, hot, or chemically aggressive place. Avoid storage in a humid environment, because the self-strengthening chain is in a humid environment, and the surface covered with water reacts with oxygen to form rust, which damages the quality of the chain and affects sales. Do not place the chain in a place where the temperature is too high or in a place exposed to direct sunlight. The direct temperature of the chain will increase the temperature of the surface of the chain and cause thermal expansion and contraction, which will change the physical characteristics of the chain and cause damage or tooth loss during use. Placing the chain in a corrosive chemical environment will seriously corrode the surface of the chain sprocket. Most of the chains generally used in corrosive environments are galvanized or nickel-plated chains. Therefore, the chain must be stored in accordance with reasonable regulations, so as to prolong the service life of the chain and reduce the manufacturer's expenses.

How to measure the model of industrial conveyor chain:

一 、 Measure the pitch of the chain and the distance between the two pins

2, the width of the inner section, this part is related to the thickness of the sprocket

Three, the thickness of the chain plate, in order to understand whether it is reinforced

4. The outer diameter of industrial conveyor chains, some of the conveyor chains use large ones

Generally speaking, the above four data can already analyze the model of the chain.

There are two types of A series and B series. The outer diameter of industrial conveyor chains with the same pitch is different. Please pay attention to this.