Features and overview of industrial chains

Overview of industrial chains:

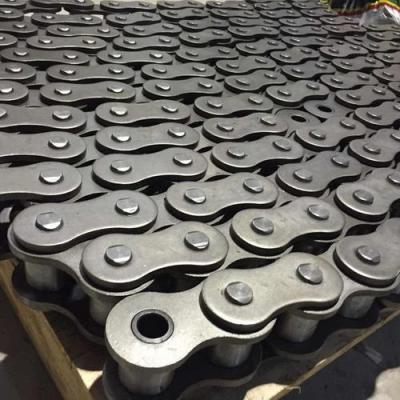

Roller Chain is a flexible component composed of adjacent identical or opposite parts. All chains used on machinery, mechanisms and machines are called industrial chains.

A closed chain and two sprocket wheels form a mechanism to realize a transmission-chain transmission. Compared with Gear drive and belt drive, this drive has the following characteristics:

(1) Multi-tooth bearing, safe and reliable;

(2) Flexible transmission, absorb shock and vibration;

(3) The center distance range is large, and the manufacturing and installation accuracy requirements are low;

(4) Compared with the belt drive, the transmission ratio is accurate and the transmission efficiency is high, which is suitable for the harsh environment of high temperature, dusty and humid.

Chain production in major industrial countries in the world: Due to the development of agricultural machinery and export needs in the United States, the production of chains was the earliest and the output was large. Affected by the United States, Japan, Canada and other countries use the American chain standard ANSI production chain. Most European countries have adopted the British BS standard. After World War II, Europe imported the standards of the American ASA Association, while Japanese marine large-pitch chains still retained the BS standard.

The industrial chain has a simple structure, is a labor- and material-intensive product, and is accompanied by noise pollution. In recent years, major industrial countries in the world have gradually replaced labor- and material-intensive products with technology-intensive products, and most have shifted from self-control to imports. At the same time, these products do not require a lot of after-sales service relative to the host or the complete set of equipment, which opens the door to convenience for China's export chain.