Sprocket and chain application precautions

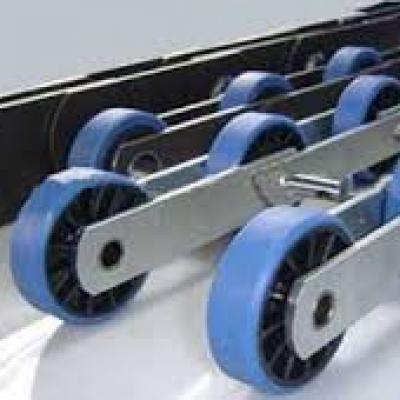

Sprockets and chains are mainly used in scraper conveyors, washing equipment, DY-100 coal mining machines, and rock loaders. The processing of the sprocket must meet the national GB1244-76 standard. Due to strict requirements in use, the quality of the Dongguan mesh belt production sprocket is good in use. The structure of the sprocket has integral type and left and right halves. The material of the sprocket should ensure sufficient strength and wear resistance. Hardness HRC> 40-45; under heavy load, surface fire treatment should be adopted.

Sprockets and chain failures are mainly caused by wear that causes the chain pitch to become longer, which causes the machine to generate additional dynamic loads, continuous impacts from the chain and sprocket, vibration and noise, and accelerated damage to accessories. Reasonably matched transmission installation equipment. Purchase qualified accessories to ensure the quality of the accessories. Replace qualified sprocket in time to reduce chain wear. Replace the bearings that support the sprocket in a timely manner to prevent the gap from becoming too large and causing the center of the sprocket to skew.

The greater the transport capacity and the longer the laying length, the greater the torque of the sprocket. Therefore, the processing of the sprocket is required to be standardized to ensure toughness and pulsating load and additional impact, which has a considerable service life.