Understand the importance of chain and maintenance

The importance of chains

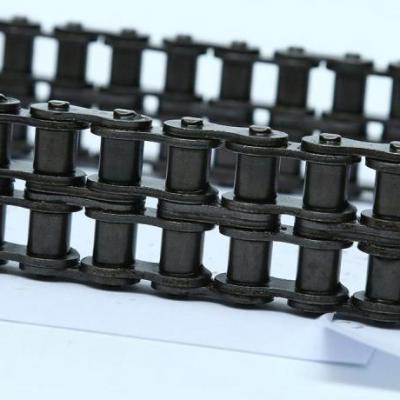

After years of development, today's chains are quite rich in variety. For example: the most widely used precision roller chains, sleeve chains or long-pitch roller chains for transmission, etc .; but in terms of their uses, the current chains are basically Transmission Chains and Conveyor Chains. And the material of the chain has also broken a lot, including corrosion-resistant stainless steel chain, powder metallurgy chain and so on. In addition, different types of chains can be used according to different working environments to maximize the production efficiency of various production industries.

Today, the manufacturing technology of the chain is basically mature and can reflect the reliability of the industrial chain. For example, compared with the traditional belt drive, the transmission efficiency of the industrial chain is higher and more accurate. The current chains are all manufactured by machines, advanced heat treatment technology, and finally stamped and formed. The biggest advantage is that the conveying effect can be performed perfectly even in the harsh working environment. Therefore, the chain can be applied to the transportation industry, light textile industry, metallurgy and high precision instrument industry.

Maintenance and care of the chain

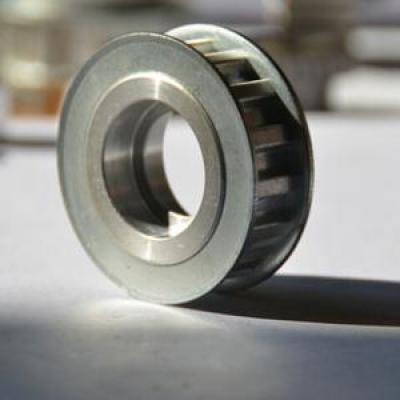

1. The sprocket should be installed on the shaft without skewing and swinging, and it is not allowed to rub the side surface of the sprocket teeth. If the deviation of the two wheels is too large, it will easily cause off-chain and accelerated wear. In addition, check and adjust the offset when replacing the sprocket.

2. The tightness of the chain should be appropriate. Too tight will increase the power consumption and the bearing will be easy to wear. If it is too loose, the chain will easily jump and delink.

3. The new chain is too long or stretched after use, and it is difficult to adjust. If this kind of phenomenon occurs, you can remove the chain links depending on the situation, but it must be an even number, and the chain links should pass through the back of the chain, the locking piece is inserted outside, and the opening of the locking piece should face the opposite direction of rotation.

4. If the sprocket is severely worn, the new sprocket and new chain should be replaced at the same time to ensure good meshing. Remember: you cannot replace the new chain or sprocket alone, otherwise it will cause poor meshing and accelerate the wear of the new chain or sprocket.

5. The old chain cannot be mixed with part of the new chain, so it is easy to generate impact in the transmission and pull the chain off.

6. Remember to fill the chain with lubricating oil in time in order to improve working conditions and reduce chain wear.