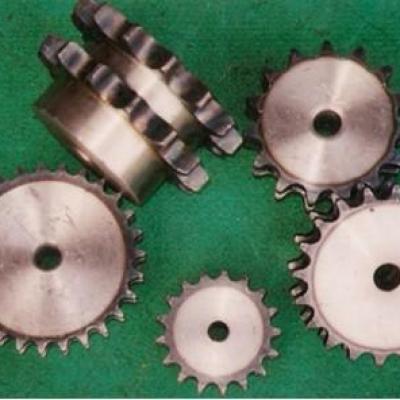

Understand The Sprocket

Sprocket Applications: Widely used in chemical industry, textile machinery, food processing, instrumentation, machinery and other industries.

Sprocket parameters formula:

Indexing circle diameter: d = p / sin 180 ° / z p = pitch can be found in the table z = number of teeth

Front circle (outer diameter): D = p × (0.54 + cot180 ° / z)

3/8 = 9.525 1/2 = 12.7 5/8 = 15.875 3/4 = 19.05

\ 3 points 4 points 5 points 6 points

Diameter circle: d = p / sin (180 ° / z)

Tip diameter: dmax = d + 1.25p-d1

Dmin = d + (1-1.6 / z) p-d1

Dedendum diameter: df = d-d1

Note: p chain pitch

Z sprocket number of teeth

D1 Chain roller diameter

Sprockets Model: Contains non-standard sprockets (customized according to customer drawings), standard sprockets (American standard and metric).

Sprocket commonly used materials: C45

Common sprocket processing methods are: quenching, surface blackening treatment

The general principle of selection of sprocket teeth:

19 or more

Generally used for high-speed, active sprocket normal working condition.

17 teeth

Applies only to small pitch sprockets.

23 teeth or more than 23 teeth

Recommended for use in collision situations. When the speed is relatively low, with a large number of sprocket Gears can greatly reduce the chain rotation, the chain of tensile load and bearing load.

Structure Design of Roller Sprocket

1. Sprocket tooth shape

The profile of the sprocket must ensure smooth and smooth engagement of the chain energy, minimizes the effects of meshing and contact stress and is also easy to machine.

Sprocket material

Sprocket material should ensure that there is sufficient strength and wear resistance, so the sprocket tooth surface are generally heat treatment, to reach a certain hardness.