Structural design of roller chain sprocket

The tooth shape of the sprocket

The ISO Sprocket tooth shape must ensure that the chain can smoothly and freely enter and exit the mesh, minimize the impact and contact stress of the link during the meshing, and be easy to process. The commonly used sprocket face tooth profile is shown in Figure 1. It is composed of three arcs aa, ab, cd and a straight line bc, referred to as a three arc-linear tooth shape. The tooth profile is machined with a standard tool. It is not necessary to draw the face tooth shape on the sprocket work diagram. Just indicate "the tooth shape is manufactured according to 3RGB1244-85" on the drawing, but the axial tooth profile of the sprocket should be drawn. See Figure 2 for dimensions and refer to the relevant design manual. Parameter calculations have been mentioned before, no repetitive narrative!

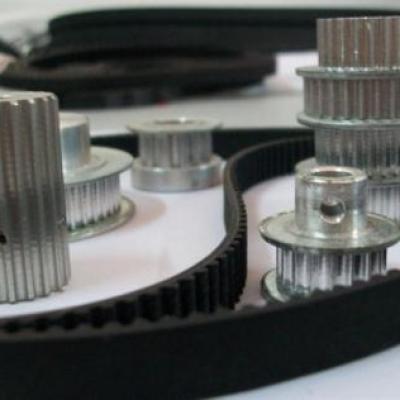

2. ASA Sprocket structure Figure 3 shows the four commonly used sprocket structures. The small-diameter sprocket is generally made in one piece (Fig. 3a). The medium-diameter sprocket is mostly made of a web. For easy handling, loading and weight reduction, the hole is opened on the web (Fig. 3b). The large diameter sprocket can be used. Made in combination (Fig. 3d), the ring Gear and the wheel core can be made of different materials! For example, C45, stainless steel and other materials.

3. Taper lock Sprocket material The sprocket material should ensure that the gear teeth have sufficient strength and wear resistance, so the sprocket tooth surface is generally heat treated to achieve a certain hardness.