Sprocket product classification and product development status

Sprocket product classification and product development status

As the main basic transmission part, the sprocket product is characterized by long-distance transmission without affecting the speed ratio (in comparison: the Gear is conveyed at a short distance, and the teeth are intersected for transmission, and the speed ratio is equal). Sprocket products have now become indispensable and important mechanical basic transmission products in the national economy, and are widely used in mining machinery, agricultural machinery, construction machinery, forestry machinery, petrochemicals, automatic assembly lines and other transmission machinery. Sprocket products can be seen Wide application.

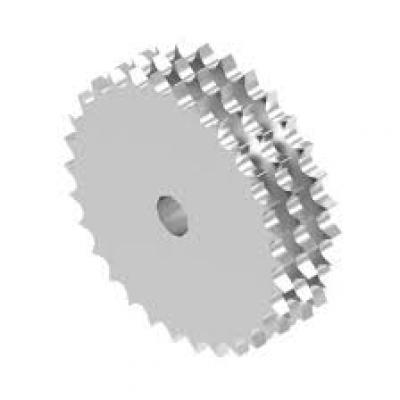

Chain drive is a non-conjugate meshing drive with intermediate flexible parts. It has some characteristics of gear drive and belt drive. Sprocket and chain products are the basic parts of mechanical transmission. In order to ensure the interchangeability of meshing, the sprocket must be standardized with the matching chain. Due to the difference in the number of teeth and the structural form, there are often hundreds of sprockets used with chains of the same specification. Therefore, for a long time, there has been a situation in which various factories design and manufacture sprockets by themselves. In recent years, due to the increasing demand for sprocket products in the international market, this situation will certainly promote the marketization of my country's sprocket products, and will also promote the rapid development of my country's sprocket industry.

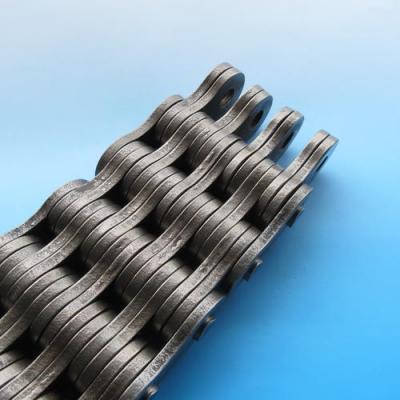

With the acceleration of the marketization and internationalization of sprocket products, the classification of sprocket is gradually standardized. From the classification of sprocket products, it is mainly divided into two categories: A series (American standard) and B series (European standard). The A series are sizes and specifications that comply with American and Japanese standards, and the products are mainly used in the American and Asian markets; the B series are sizes and specifications that comply with the European chain standards and are mainly suitable for the European market. A series and B series are divided into three types: slice type, single-side convex table type, and two-side convex table type. The slice type is A type, the single side belt convex table is B type, and both sides belt convex table is C type. The three types of A, B, and C are divided into single-row, double-row, three-row, four-row, etc. according to the difference of the chain; according to the type of the chain, they are divided into short-pitch precision Roller Chain sprockets and long sections. Distance from precision roller chain sprockets, Conveyor Chain sprockets, etc.

With the development of my country's economy and the deepening of market understanding of chain drive mechanism, the level of sprocket tooth profile design is also constantly improving. my country has always used the three-arc straight tooth profile of the former Soviet Union and Europe. Although the transmission performance is better, the design and manufacture are relatively complicated. The chain drive composed of the involute tooth profile with a 30-degree pressure angle introduced by the American Morse Company is called the HV chain drive, which has good high-speed transmission performance. Another notable feature is the application of CAD/CAM technology, which directly promotes the development of sprocket technology. Sprocket drawing software has entered the market. Using these software, you only need to input the relevant parameters, such as the relevant size of the chain, the structure of the sprocket, the number of teeth, etc., and you can quickly draw the sprocket work diagram. Third, non-circular sprocket technology has been developed and applied. For example, the drive sprocket called ergonomics on a variable speed bicycle is a non-circular sprocket. This kind of sprocket helps reduce the adverse effect on the transmission efficiency when the bicycle drive sprocket is in a vertical position, and has been widely promoted and applied.

At present, standard sprocket products (specification and uniform size) cannot meet the growing social needs. S-type and C-type steel roller sprocket, flat top sprocket, tooth sprocket, traction sprocket The market demand for metric chain sprockets, conveyor chain sprockets and die forging chain sprockets is gradually increasing. With the continuous improvement of the status of mechanical transmission parts in the national economy and the degree of marketization, my country's mechanical sprocket industry is ushering in a new development opportunity. At present, the output of transmission parts such as sprockets and gears in my country has ranked in the forefront of the world, and due to the adjustment of the world economic structure, my country has gradually become a manufacturing base for labor and raw material-intensive products, while transmission parts such as mechanical sprockets have Such products naturally attract foreign buyers to purchase. At the same time, foreign manufacturers are also accelerating the pace of investing and setting up parts and components companies in China. Most of their products are exported, and the other part is sold domestically. With the further integration of domestic and foreign markets and the advent of global procurement of transmission products such as sprocket, the domestic sprocket market is promising, and orders from foreign OEM customers are gradually increasing. It should be said that this is not only a good development opportunity for the sprocket industry, but also fierce competition and challenges.

From the current development status of sprocket products, my country's sprocket products can no longer meet the development requirements of domestic and international markets. Mainly because there are not many large-scale modern and large-scale production enterprises in China’s sprocket enterprises, the production process has not been improved for a long time, the transformation of production equipment often lags behind the needs of product development, and the brand awareness of sprocket products is weak (domestic Sprocket products are nationally famous brand products, and almost zero are international brands. Most of the exported sprocket products are OEM production), the added value of sprocket products is low, and the specialized technical force is generally weak , Market competition is not very standardized, and so on. These factors have severely restricted the development of China's sprocket industry. However, with the acceleration of foreign manufacturers' investment and establishment of sprocket enterprises in China, the new round of development has taken the lead. Many domestic sprocket enterprises have increased equipment upgrades and technological transformations, and improved corporate management. It will surely bring the overall level of the entire sprocket industry to a new level. The basic construction and technological transformation of sprocket enterprises have shifted from quantitative expansion to qualitative improvement. Generally, small and medium-sized enterprises have begun to pay attention to the transformation and renewal of old equipment and the investment in advanced equipment on the basis of extensive technological transformation in the past few years. On the one hand, large and medium-sized backbone enterprises make up for their own actual needs in terms of technological transformation, and on the other hand, they boldly innovate on the basis of summing up experience. While the original state-owned enterprises in the industry are undergoing restructuring, reorganization or shareholding reform, the rapidly rising private enterprises and joint-stock enterprises have become the main force in the general machinery parts industry. At present, more than 90% of the main key enterprises in my country's sprocket industry are private or joint-stock enterprises, and there are almost no state-owned enterprises.

From the overall development of the sprocket industry, the standard sprocket will gradually shrink, and the market demand will gradually decline; the demand for non-standard sprocket products (the size is determined according to the customer’s drawings) and the total sprocket The market share of sprocket will increase significantly. It should be said that non-standard sprocket is a development direction of the entire sprocket product, with great market potential and broad development prospects. At the same time, because the timing belt pulley has both the advantages of pulley transmission and the characteristics of sprocket transmission, the market share of timing belt pulleys in the entire chain transmission products will be greatly increased, and its development prospects will also be very optimistic. The market potential will be immeasurable. In summary, non-standard sprockets and synchronous belt wheels represent the future development direction and general development trend in the entire series of transmission parts such as sprockets. They have huge market potential and broad development prospects.