Notes on supply chain wheels and analysis of common problems

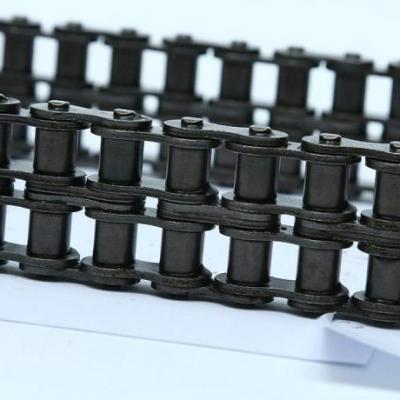

Sprockets are mainly divided into mechanical sprocket, motorcycle sprocket, stick sprocket, double-row sprocket, mining machinery sprocket and transmission sprocket. Mechanical sprocket welding structure is mainly used in the processing of medium and large size single and double flange sprocket. During processing, the flange part is convexly shaped by a bar stock car. Ordinary keyway on the shaft of motorcycle sprocket: In the case of ordinary grooves on the outer circle of the shaft, it uses clamps and bolts to clamp the shaft on the V-shaped iron. The sprocket is directly clamped on the side of the planer workbench. Since the side of the workbench and the upper plane are perpendicular to each other, the processing requirements can be guaranteed. The tooth profile of the roller sprocket must ensure that the chain can enter and exit the meshing smoothly and energy-savingly, minimize the impact and contact stress of the chain link during meshing, and be easy to process. A double-row sprocket is a wheel with a cog-type chain sprocket, which is used to mesh with a pitch chain block or a cable with a precise pitch. It is a solid or spoked Gear that meshes with a (roller) chain. To pass motion. Mining machinery sprocket wheels with cog-type sprocket wheels for meshing with accurate pitch on the chain link or cable. Mining machinery sprocket wheels are widely used in chemical industry, textile machinery, food processing, instruments, Mechanical transmission in petroleum and other industries. The driving sprocket is divided into a driving sprocket and a driven sprocket. The driving sprocket is mounted on the engine output shaft through a spline; the driven sprocket is mounted on the motorcycle driving wheel and transmits power to the driving wheel through the chain. Generally, the driving sprocket is smaller than the driven sprocket, which can reduce the speed and increase the torque.