What is timing pulley

Timing PulleyA timing pulley is a mechanical component used in various systems to transfer rotational motion accurately and efficiently. It is designed with teeth or grooves along its circumference that mesh with a timing belt or chain, allowing for precise power transmission. Here is an overview of timing pulleys:

Key Features and Characteristics:

Teeth Profile: Timing pulleys have specific tooth profiles (such as trapezoidal, curvilinear, or HTD) that match the corresponding profile of the timing belt for positive engagement and minimal slippage.

Pitch Diameter: The pitch diameter of the pulley corresponds to the diameter where the timing belt or chain engages with the pulley teeth, determining the speed ratio and timing accuracy.

Material: Timing pulleys are commonly made from materials like aluminum, steel, or plastic, chosen based on factors such as load capacity, durability, and environmental conditions.

Bore Size: The pulley has a central bore to mount it on a shaft or hub securely, ensuring proper alignment and efficient power transmission.

Number of Teeth: The number of teeth on the pulley affects the speed ratio and torque transmission between the driving and driven components.

Applications: Timing pulleys are widely used in industries such as automotive, robotics, printing, textile machinery, CNC machines, 3D printers, and various automated systems requiring precise motion control.

Benefits and Applications:

Precise Motion Control: Timing pulleys and belts provide accurate synchronization of rotational components, ensuring precise positioning and timing in mechanical systems.

Low Maintenance: They offer low-maintenance operation due to minimal slippage and wear compared to friction-based pulley systems.

High Efficiency: Timing pulleys transfer power efficiently with minimal energy loss, making them suitable for applications requiring high efficiency.

Noise Reduction: The positive engagement of teeth reduces vibration and noise during operation, enhancing overall system performance.

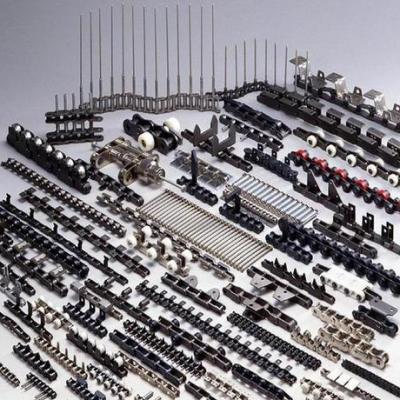

Variants and Configurations:

Different Tooth Profiles: Timing pulleys are available in various tooth profiles to accommodate different belt types and applications.

Single and Double Flange: Pulleys can feature single or double flanges to guide the timing belt and prevent it from slipping off during operation.

Customization: Manufacturers offer customization options for bore sizes, tooth profiles, materials, and sizes to meet specific application requirements.

Timing pulleys play a critical role in ensuring accurate and reliable power transmission in a wide range of mechanical systems, contributing to efficient operation and precise motion control.