What are the differences between industrial transmission sprocket and split type transmission sprocket

Industrial Transmission Sprocket vs. Split Type Transmission SprocketIndustrial transmission sprockets and split type transmission sprockets serve similar functions in power transmission systems but differ in their design and application. Here are the key differences between the two types of sprockets:

Industrial Transmission Sprocket:

Design:

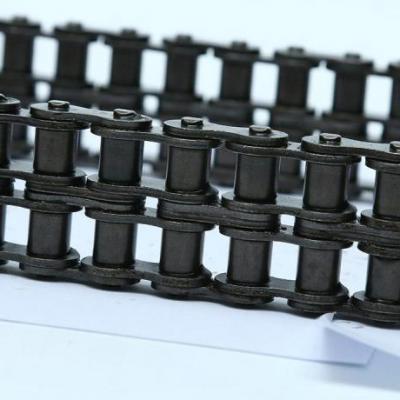

Industrial transmission sprockets are typically one-piece sprockets with a solid construction.

They feature a continuous, solid design with integrated teeth around the entire circumference of the sprocket.

Application:

These sprockets are commonly used in heavy-duty industrial applications such as conveyors, machinery, and equipment where robust and reliable power transmission is required.

Industrial transmission sprockets are suitable for high torque and heavy load applications.

Installation:

They are typically mounted on shafts or hubs using set screws, keyways, or other fastening methods to ensure a secure connection.

Installation may require disassembling parts of the machinery or equipment to mount the sprocket.

Split Type Transmission Sprocket:

Design:

Split type transmission sprockets feature a two-piece or split design, allowing for easier installation and removal without the need to disassemble the entire system.

They consist of two halves that can be bolted together around the shaft, simplifying maintenance and replacement.

Application:

Split type transmission sprockets are often used in applications where frequent maintenance, repair, or sprocket replacement is anticipated.

They offer convenience in situations where quick access to the sprocket for maintenance or adjustment is necessary.

Installation:

The split design of these sprockets allows for easy installation and removal by simply separating the two halves and securing them around the shaft.

They are ideal for applications where downtime needs to be minimized during maintenance or repairs.

Key Differences:

Installation Convenience: Split type transmission sprockets offer easier installation and removal compared to industrial transmission sprockets, which may require more disassembly.

Maintenance Ease: Split sprockets facilitate quick access for maintenance, repair, or replacement tasks without extensive system disassembly.

Application Flexibility: Industrial transmission sprockets are suitable for heavy-duty applications, while split type sprockets provide convenience in applications with frequent maintenance needs.

Both types of sprockets have their advantages depending on the specific requirements of the application, maintenance considerations, and ease of installation and removal. The choice between industrial transmission sprockets and split type transmission sprockets will depend on factors such as operational needs, maintenance frequency, and system design preferences.