Two processing methods of gear tooth profile

There are two ways to process Gear tooth profile. One is the forming method, which uses a forming milling cutter that exactly matches the tooth groove shape of the gear to be cut, such as tooth milling; the other is the generative method, which uses the interaction between the gear cutter and the driven gear. The machining method of cutting out the tooth profile by meshing movement, such as gear hobbing and gear shaping (use hob and inserting knife for demonstration). The following describes the method of machining gears with a milling machine.

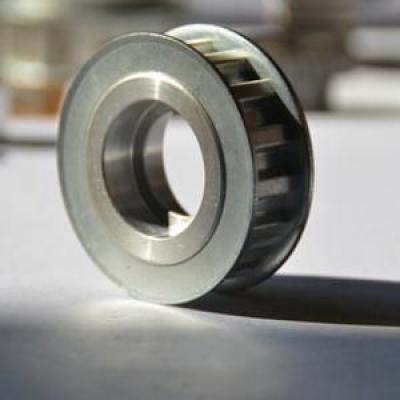

For processing bevel gears (straight bevel gears) on a milling machine, the milling cutters used by vertical milling machines and horizontal milling machines are different. Finger gear milling cutters are used on vertical milling machines because the manufacturing cost of finger gear milling cutters is high. , Easy to wear, poor chip removal and heat dissipation during use, so it is rarely used. Under normal circumstances, disk gear milling cutters are often used for processing on horizontal milling machines; the tooth profile of the bevel gear disk gear milling cutter is made according to the tooth profile of the big end of the bevel gear, and the thickness is made according to the small end of the bevel gear. Before processing, press Select the number of teeth, the wheel blank is installed on the spindle, the spindle is clamped on the indexing head, the elevation angle of the indexing head is adjusted to be consistent with the angle ψ between the tooth root line of the bevel gear and the center line, and the wheel blank is aligned The milling cutter is centered and milled to the full tooth depth h=2.2m according to the large-end modulus. The tooth thickness of the large-end is measured, and all the tooth spaces are milled; then the margin on both sides of the large-end is milled, and the worktable has a lateral displacement. The formula is S=mB/2L (m--modulus, B--tooth surface width, L--pitch radius). Rotate the indexing head so that one side of the milling cutter just rubs against the side of the small end tooth groove. After milling, measure the tooth thickness of the big end. At this time, the tooth thickness of the big end is the margin of the actual tooth thickness + 1/2. Side allowance until all tooth slots are milled.

That is, bevel gears (Bevel), bevel gears. Used for transmission between intersecting shafts. The single-stage transmission ratio can reach 6, the maximum is 8 or above, and the transmission efficiency is generally 0.94~0.98. 1) The design, manufacture and installation of spur and helical bevel gears are relatively simple, but they are noisy and are used for low-speed transmission (<5m/s); the transmission power of spur bevel gears can reach 370 kilowatts, and the peripheral speed is 5 meters. /second. The transmission of helical bevel gears runs smoothly, and the load-bearing capacity of the gears is high, but it is difficult to manufacture and has fewer applications. 2) Curved bevel gears have the characteristics of stable transmission, low noise and large carrying capacity, and are used in high-speed and heavy-duty situations. Curved bevel gear transmission runs smoothly, the transmission power can reach 3700 kilowatts, and the circumferential speed can reach more than 40 meters per second.