The difference between sprocket drive and synchronous belt pulley

Sprocket drives and synchronous belt pulleys are both mechanisms used to transmit power and motion in machinery, but they operate on different principles and have distinct characteristics. Here's a detailed comparison:1. Sprocket Drive

Definition:

A sprocket drive uses a sprocket (a toothed wheel) and a chain to transmit motion. This system is commonly seen in bicycles and motorcycles.

Key Components:

Sprocket: A wheel with teeth that mesh with a chain.

Chain: A series of linked segments that fit over the sprocket teeth.

Operation:

The teeth of the sprocket engage with the links of the chain, transferring rotary motion and torque. The chain wraps around the sprocket and transmits force from one sprocket to another, typically from a driving sprocket attached to a motor to a driven sprocket on a load.

Advantages:

High Torque Transmission: Capable of handling high loads.

Durability: Chains and sprockets are robust and long-lasting.

Positive Drive: No slip, ensuring precise timing and motion transfer.

Adjustability: Easy to change the length of the chain and sprocket sizes.

Disadvantages:

Noise: Chains and sprockets can be noisy during operation.

Maintenance: Requires regular lubrication and tension adjustment.

Wear: Chains and sprockets wear over time and may need replacement.

2. Synchronous Belt Pulley

Definition:

A synchronous belt pulley system uses a toothed belt and matching toothed pulleys to transmit motion. It is also known as a timing belt system.

Key Components:

Pulley: A wheel with grooves or teeth that mesh with the belt.

Synchronous Belt: A belt with teeth on its inner surface that match the pulley grooves.

Operation:

The toothed belt meshes with the pulley grooves, allowing for precise synchronization of the driving and driven shafts. This system ensures that the motion is transmitted without slippage.

Advantages:

Quiet Operation: Generally quieter than chain drives.

Low Maintenance: Does not require lubrication, reducing maintenance needs.

Precision: Provides precise timing and positioning.

Efficiency: High efficiency with minimal power loss.

Disadvantages:

Load Capacity: Typically handles lower torque compared to chain drives.

Environmental Sensitivity: Can be affected by extreme temperatures and contaminants.

Stretching: Belts can stretch over time, requiring tension adjustment or replacement.

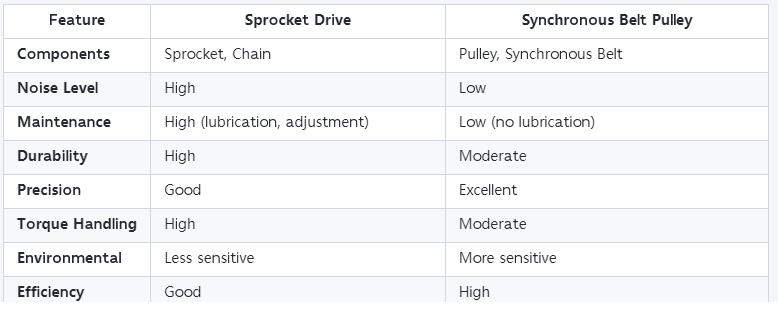

Comparison Summary:

Each system has its own strengths and is chosen based on specific requirements such as load capacity, maintenance preferences, noise considerations, and the need for precision.