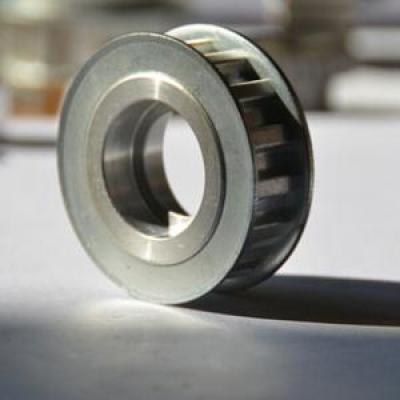

Sprocket maintenance:

1, the tightness of the sprocket should be appropriate, too tight will increase the wear and tear, easy to wear bearings; loose sprocket too easy to be knocked down. Looseness of the sprocket: lifted or pressed in the middle of the sprocket, the center distance between the two sprockets is about 2% -3%.

2, the sprocket mounted on the shaft should not swing and skew. In the same transmission, the two sprocket end faces should be in the same plane, sprocket center distance less than or equal to 0.5m, the deviation can be 1mm; sprocket center distance of 0.5 meters or more, the deviation can be 2 mm. However, no friction sprocket flanks are allowed. If the two deviations are too large, it is easy to cause the chain and accelerated wear and tear. Care must be taken to check and adjust the offset when changing sprockets.

3, serious wear sprocket should be replaced at the same time the new sprocket to ensure good engagement. You can not just replace the new sprocket. Failure to do so can result in poor engagement, thereby accelerating the wear of old or new sprockets. Sprocket tooth wear must be promptly replaced to extend the use of time.

4, the sprocket should work in time to cheer. Lubricating oil must enter the mating gap between the drum and the inner sleeve to improve working conditions and reduce wear.

5, the old sprocket can not be mixed with some new sprocket, otherwise easy to produce impact in the drive, pull off the sprocket.