Learn how to calculate synchronous pulleys and use synchronous pulleys reasonably

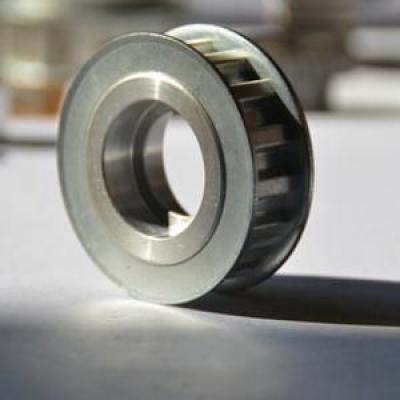

Synchronous pulley product use:

The synchronous belt pulley can be allowed to work in the places with pollution and relatively harsh working environment. Widely used in automotive, textile, printing and packaging equipment

Equipment, sewing equipment, office equipment, laser engraving equipment, tobacco, financial machinery, stage lighting, communication food machinery, medical machinery, steel

Iron machinery, petrochemical industry, instrumentation, various precision machine tools and other fields.

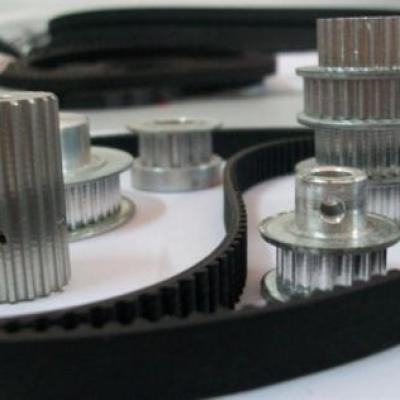

Timing belt drive design:

a. The number of meshing teeth of the synchronous belt and the small pulley should be ≥6, if the mechanism allows, it can be increased by increasing the center distance, or the diameter of the pulley does not change

Under the circumstances, the small pitch is used, but it should be allowed by the force.

b. Timing belt width, pitch and pitch line length Due to the determination of the timing belt width, the calculation formula is complicated, so it is often used in actual design

Calculate the circumferential force, and then refer to the allowable circumferential force to find the corresponding bandwidth and pitch in the relevant mechanical design manual, generally 5.08. In the determined section

After the distance and bandwidth, the length of the pitch line is calculated according to the initial center distance, and then selected according to the standard. If it does not meet, the center distance can be adjusted.

c. The tooth shape of the synchronous belt of the head mechanism of the computer flat knitting machine generally chooses a circular arc shape, and some selects a trapezoid shape, but no matter what kind of tooth shape should be satisfied

A circle on the pulley is tangent to the pitch line of the belt, and pure rolling is performed.The second is that the distance between the corresponding points of two adjacent teeth on the pulley on this arc is the same

The pitch of the step belt. In order to ensure good performance when the belt is engaged with the pulley, the tooth profile angle of the pulley should be correctly selected when designing, according to Japan's Yamatofu

During the experiment and the actual trial production process of our factory, it was found that when the tooth profile angle is 20? ~ 25 ?, the interference between the Gear tooth and the belt tooth is small, and the tooth profile angle is deviated.

The difference is about? Font face = "Times New Roman"> 1 ?.