What to use for shaft and bearing

Coordination of shafts and bearings:(1) Bearing cooperation is generally a transitional cooperation, but in special circumstances, the conference can be selected, but it is rarely;

(2) Because the coordination of bearings and bearing is the inner ring and shaft of the bearings, the base hole system is used. Originally, the bearing should be completely zero. When the minimum limit size of the shaft is matched, the internal ring rolling and the surface of the damage shaft are generated, so our bearing inner ring has a lower partial tolerance of 0- a few UM to ensure that the inner ring is not rotated, so the bearings generally choose a transition cooperation. , Even if you choose a transition coordination, you cannot exceed the amount of 3 wires;

(3) The accuracy level is generally selected at level 6. Sometimes it depends on the materials and the processing process. Theoretically, the accuracy of 7 levels is a bit low.

(4) The general selection is:

Coordinate with the bearing inner ring with the axis, select K6;

…. , ... holes ..., Kong Choose K6 or K7

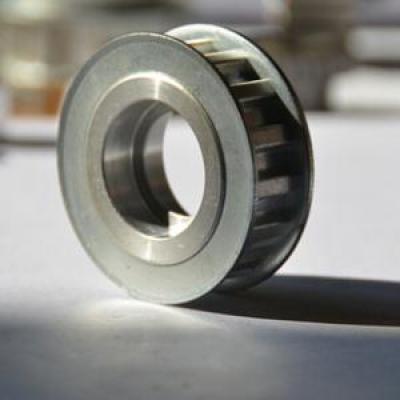

Coordination of shafts and belt wheels:

The motor shaft and belt wheel clearance is matched, and then the positioning key is added. If it is excessively coordinated, the heat and expansion of the motor shaft will increase the worst belt wheel, so there must be a gap!