Types and functions of basic chains

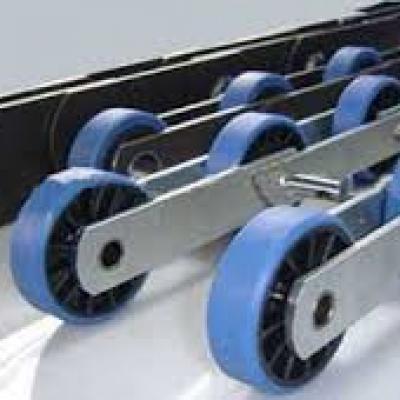

The structure of the Conveyor Chain is composed of inner and outer links, and it is also composed of five small parts: inner link plate, outer link plate, pin, sleeve, and ball. The quality of the chain depends on the pin and sleeve. The conveying chain is divided into conveying short-pitch roller chains, double-pitch roller chains, curved plate roller chains for heavy-duty transmission, long-pitch conveying chains, and short links. Distance conveyor chain, double-pitch roller conveyor chain, etc. Today we will talk about the choice and application of basic chain for everyone.

1. The standard drive Roller Chain is a universal drive roller chain based on JIS and ANSI specifications.

2. Anti-rust chain is a nickel-plated chain.

3. The plate chain is a hanging chain composed of a chain plate and a pin.

4. The stainless steel chain is a stainless steel chain that can be used in special environments such as medicine, water and high temperature.

5. Hollow pin chain is a chain connected by hollow pins, and accessories such as pins and cross bars can be freely added or removed according to customer requirements.

6. Double-pitch roller chain (type A) is a double-pitch chain based on JIS and ANSI standards. It is a low-speed Transmission Chain with a light weight and average length, and is suitable for installations with long distances between shafts.

7. The standard accessory chain is a chain with additional accessories on the standard roller chain for transmission.

8. Double-pitch attachment roller chain is a chain with attachments attached to the double-pitch roller chain. It is mainly used for transportation.

9. Double-pitch roller chain (C type) is a double-pitch chain based on JIS and ANSI standards. It is mainly used for low-speed transmission and handling. There are standard diameter S-type rollers and large diameter R-type rollers.

10, ISO-B type roller chain is based on ISO606-B roller chain. Britain, France, Germany and other imported products use more of this type.