The difference between the use of sprocket drive and synchronous belt drive

The occasions used between the sprocket and the synchronous belt wheel are actually the same, but there are certain differences in use.

1. On occasions where a relatively large force is required, such as a low-speed heavy load occasion, it is necessary to use a sprocket as a transmission tool, because the force of the sprocket is relatively large.

2. In order to prevent the occurrence of vibration or if it needs to be buffered, if the applied force does not need to be too large, it is recommended to use a synchronous pulley for transmission.

3. For occasions where noise requirements are relatively high, or in the more important occasions such as the shield door of the subway, it is generally recommended to use a synchronous pulley for transmission.

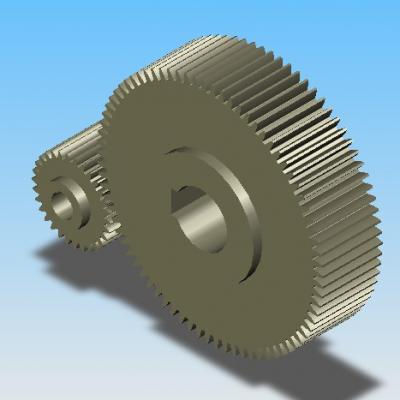

Scope of application of sprocket

Due to its own characteristics, sprockets are widely used in chemical industry, textile industry, food processing and transportation industry, instrumentation industry, petrochemical industry and other mechanical transmission.

Scope of application of synchronous pulley

Due to its own advantages, synchronous pulleys are widely used in various precision machinery fields such as automobile industry, printing industry, office equipment, tobacco manufacturing, and medical equipment.

Advantages of Timing Pulleys

1. The output power of the synchronous pulley can reach 0.8 kilowatts, and the running speed can be as high as 20,000 hours per hour.

2. The timing pulley can allow the use of smaller pulleys, the diameter of which can reach 6 mm.

3. The timing pulley can have the largest number of mesh teeth.

4. Timing pulley can use high stepping motor as power output.

5. The synchronous belt pulley has a very high-precision positioning system during operation.

6. The timing pulley is very accurate and stable during operation.