Structure and working principle of double speed chain

1.Definition of double speed chain

的 The chain used for material transportation is similar to the chain used for chain transmission. The most commonly used Conveyor Chain in engineering is the roller chain.

The so-called double plus conveyor chain is such a roller conveyor chain. On the conveyor line, the moving speed of the chain remains the same, but the tooling plates and workpieces conveyed above the chain can be controlled and moved according to user requirements. Beat, stop the movement at the position where you need to stay, and perform various assembly operations by the operator, and then continue to move the workpiece forward after completing the above operations. Therefore, the double-speed conveyor chain can also be called a beat conveyor chain, a free-beat conveyor chain, a double-speed chain, a differential chain, and a differential chain.

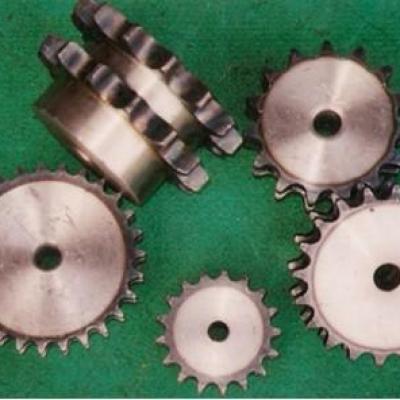

2, Structural composition of double speed chain

Double-speed chain consists of six kinds of parts: inner link plate, sleeve, roller, roller, outer link plate and pin.

(1) Part material

Under normal circumstances, the rollers and rollers are injection-molded from engineering plastic materials. Steel materials are used only under load. In addition, the other parts are made of steel.

(2) Parts connection method

The structure of double speed chain is similar to that of ordinary Double Pitch Roller Chain, where:

① Pin and outer link plate: The pin and outer link plate adopt an interference fit to form a link frame.

② Pin and inner link plate: Both the pin and inner link plate are clearance fit to make the chain bend.

③ Pin and sleeve: There are two ways to connect pin and sleeve. One type is that the sleeve is inserted into the inner link plate and is in interference fit with the inner link plate; the other is that the sleeve is not inserted into the inner link plate and the sleeve is directly sleeved on the pin shaft. In both cases, there is a clearance fit between the sleeve and the pin.

(A) The sleeve is inserted into the inner link plate and interference fit with it; (b) The sleeve is not inserted into the inner link plate

④Sleeve and roller: There is a clearance fit between the sleeve and the roller, and relative rotation can occur between them.

⑤Roller and roller: There is a clearance fit between the roller and the roller. Relative rotation between them can occur to reduce the wear and tear of each other during work, which is very important for continuous long distance transportation.

(3) Connecting chain links: In order to form a closed ring structure, the double-speed chain also needs a connecting member like other roller chains, which is called a connecting chain link. After the connecting chain links connect the two ends of the chain, it must also be loaded with Locks to prevent the connecting links from falling off.

3.Working principle of double speed chain

(1) The role of each part

①Roller

When the double-speed chain is used, it is directly placed on the support surface of the guide rail under the chain by rollers, the rollers are in direct contact with the support surface, the lower part of the roller is suspended, and the upper part of the roller is directly placed the tooling plate for loading the workpiece, so the roller is Direct load-bearing components must bear the weight of the tooling board and the weight of the workpiece being transported on the tooling board.

② Roller: The roller is a direct load bearing component. It must not only bear the weight of the tooling board and the weight of the workpiece being conveyed on the tooling board, but also roll on the guide rail. At the same time, the drive of the chain is driven by the drive. The Gear teeth of the sprocket are directly meshed with the rollers.

③Internal and external chain plates and pins: The internal and external chain plates and pins are the connecting parts of the chain, so that a single roller wheel is connected in series to form a chain.

④Sleeve: The sleeve is used to reduce the friction between the pin and the roller to protect the pin.

(2) Speed-up principle of double-speed chain

The double-speed chain is called a double-speed chain, a differential chain, and a differential chain because it has a special speed-increasing effect, that is, the movement of the tooling plate (including the workpiece being transported on the tooling plate) placed above the chain. The speed is greater than the forward speed of the chain itself. This effect is due to the special structure of the double-speed chain. The following is a simple analysis and calculation of the reasons for the above-mentioned speed increase effect.

① The roller rolls on the guide rail, and the movement between the roller and the guide rail is pure rolling;

② There is no relative movement between the roller and the roller;

③ There is no relative movement between the tooling plate (the workpiece is placed on it) and the roller.

Set the forward speed of the chain to v0, the forward speed of the tooling plate (workpiece) to v, the diameter of the roller to d, and the diameter of the roller to D.

According to the above assumption, because there is no relative movement between the roller and the roller, the roller and the roller can be regarded as rigidly connected at the moment of rolling, and the instantaneous rolling of the two can be regarded as the roller and the rail contacting Point P is the rotation of the center of rotation.

Assume that the instantaneous rotation angle of the roller and the roller is w, so the tangent speed of the geometric center of the roller is the forward speed v0 of the chain, and the tangent speed of the fixed point above the roller is the forward speed v of the tooling board (workpiece).

V0 = wd / 2 (Equation 1)

V = w (d / 2 + D / 2) (Equation 2)

V = (1 + D / d) v0 (Equation 3)

Among them, d——roller diameter;

D——roller diameter;

W——the instantaneous rotational angular velocity of the roller and the wheel;

V0——tangent speed of the geometric center of the roller (forward speed of the chain);

V——Tangent speed of the vertex above the roller (forward speed of tooling board or workpiece).

Analysis: An analysis of Equation 3 reveals that since the roller diameter D can be doubled to be larger than the roller diameter d, the forward speed v of the tooling plate (workpiece) can make the chain advance several times the speed of v0, which is the increase of the double-speed chain. Speed effect principle, increasing the diameter ratio D / d of the roller can increase the speed increasing effect of the double speed chain.

In fact, the previous assumption and the actual situation are at a certain distance. There is inevitably moving friction between the kinematic pairs, and there may also be some sliding between the roller and the guide rail. The actual speed increase effect shown is greater than that in formula 3. The theoretical calculated value is small.

The speed-increasing effect is an important technical index of the double-speed chain. Due to the poor design and manufacturing accuracy of the poor-quality chain, the speed-increasing effect will be very poor. Because the speed increasing effect is directly related to the diameter of the roller and the roller, according to formula 3, as long as the diameter ratio D / d of the roller is increased, the speed increasing effect of the double-speed chain can be increased, and the diameter of the roller is increased by the chain. The limitation of the pitch, and the reduction of the diameter of the roller must also be limited by the chain structure. Therefore, the speed increase rate of the double-speed chain is limited. The usual speed increase effect is v = (2 ~ 3) v0. Specifications are 2.5x speed conveyor chain and 3x speed conveyor chain.